Here is the 2500-word article titled ‘Leveraging Artificial Intelligence and Advanced Food Processing Technologies’:

The culinary landscape is evolving at a rapid pace, driven by consumer demands for innovative, high-quality dining experiences that highlight local flavors and sustainable production methods. At The Loch & Quay, we are at the forefront of this transformation, leveraging cutting-edge technologies to deliver unparalleled cuisine, exceptional service, and an unforgettable ambience that captivates our discerning patrons.

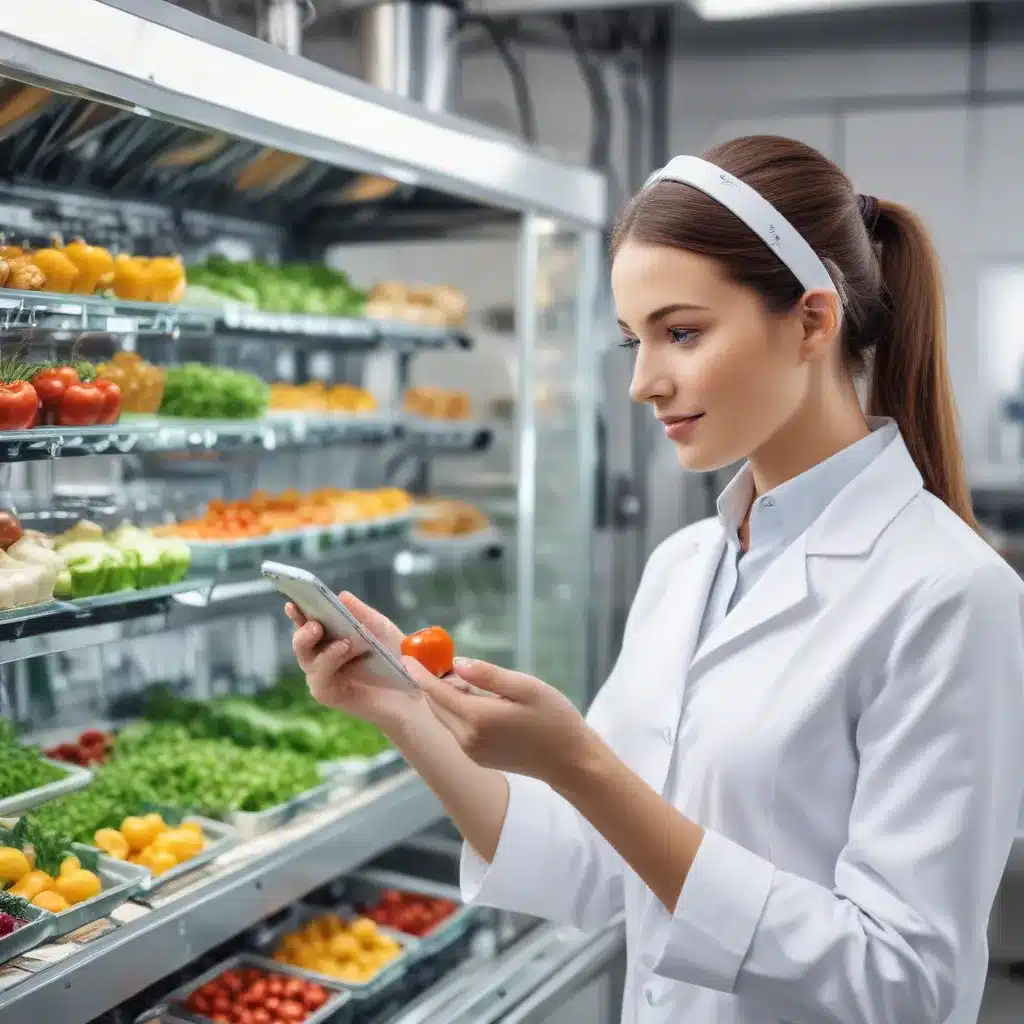

One of the key innovations transforming the food industry is the integration of artificial intelligence (AI) and advanced food processing techniques. These technologies are revolutionizing every aspect of food production, from umami-rich flavor optimization to precision quality control and traceability across the supply chain.

Machine Learning Techniques

At the heart of AI’s impact on food systems are powerful machine learning (ML) algorithms that can analyze vast datasets to uncover patterns, detect anomalies, and predict outcomes with remarkable accuracy. These ML techniques are being applied across three critical domains: food safety, food quality, and food security.

Supervised Learning plays a pivotal role in addressing these concerns. Support Vector Machines (SVMs) and Decision Trees, for example, excel at identifying contaminants and safety risks by analyzing sensor data and historical records. Similarly, Multiple Linear Regression (MLR) models predict shelf life and quality parameters based on storage conditions, while Random Forests and SVMs detect physical defects to ensure consistent product quality.

Unsupervised Learning further enhances food safety through anomaly detection. Clustering algorithms like K-means and DBSCAN identify unusual microbial profiles, spoilage patterns, and consumer feedback, enabling early intervention to prevent foodborne illness outbreaks and quality issues. Techniques like Isolation Forest and One-Class SVM also detect contaminants and equipment malfunctions, safeguarding the integrity of food products.

Deep Learning (DL) models, particularly Convolutional Neural Networks (CNNs) and Recurrent Neural Networks (RNNs), are revolutionizing visual inspection, predictive maintenance, and supply chain monitoring. CNNs automate the detection of physical defects and contaminants, while RNNs analyze time-series data to forecast spoilage and equipment failures, ensuring food safety and quality control.

AI Applications in Food Processing

The integration of AI into food processing has yielded significant improvements in operational efficiency, product quality, and safety across the supply chain.

Quality Control and Inspection: AI-powered computer vision (CV) systems leverage advanced imaging technologies to detect defects, contaminants, and irregularities in food products with unparalleled speed and accuracy. These systems ensure that only the highest-quality items reach consumers, enhancing brand reputation and building trust.

Predictive Maintenance: ML algorithms analyze sensor data from production equipment to predict when maintenance is required, preventing breakdowns and ensuring food safety by maintaining optimal hygiene standards. This proactive approach reduces unplanned downtime and minimizes the risk of contamination due to equipment failures.

Process Optimization: AI models dynamically adjust parameters for advanced food processing techniques, such as high-pressure processing (HPP), ultraviolet (UV) treatment, and pulsed electric field (PEF) processing. By continuously monitoring real-time data and optimizing operating conditions, these AI-driven systems enhance microbial safety, extend shelf life, and preserve the desired sensory attributes of food products.

Advanced Food Processing Technologies

Alongside the transformative power of AI, the food industry is also embracing a new generation of advanced processing technologies that are redefining quality, safety, and sustainability.

Novel Thermal Processing: Techniques like high-pressure processing (HPP) use intense pressure to inactivate pathogens and spoilage microorganisms, while preserving the nutritional value and organoleptic properties of food. Microwave processing and pulsed electric field (PEF) processing also offer efficient alternatives to traditional thermal treatments, ensuring food safety without compromising quality.

Non-Thermal Processing: Innovative non-thermal technologies, such as ultrasound processing, ultraviolet (UV) treatment, and ozone processing, provide effective pathogen reduction and extended shelf life, without the detrimental effects associated with heat-based methods. These technologies are particularly well-suited for temperature-sensitive foods, ensuring their safety and quality while minimizing waste.

The synergistic integration of AI and these advanced processing techniques is a game-changer for the food industry. By optimizing operating parameters, enhancing process control, and automating quality assurance, this convergence of technologies delivers consistently safe, high-quality, and sustainable food products that delight discerning consumers.

Sensor Integration and Data Analytics

The foundation of this technological revolution lies in the seamless integration of Internet of Things (IoT) sensors and robust data analytics powered by AI. IoT-enabled devices continuously monitor critical parameters, such as temperature, humidity, and microbial activity, throughout the food supply chain. This real-time data, combined with big data analytics and predictive modeling, enables proactive risk management, dynamic process control, and enhanced traceability.

Blockchain technology further strengthens this ecosystem by providing an immutable, decentralized record of transactions and product information. The integration of blockchain with IoT sensors and AI-driven analytics ensures transparency, traceability, and accountability, empowering consumers to make informed choices and building trust in the food system.

Automation and Robotics

Automation and robotics, powered by AI, are transforming food processing and handling, improving efficiency, consistency, and safety. Robotic systems equipped with CV capabilities perform precise tasks, such as sorting, grading, and packaging, with meticulous accuracy, ensuring product quality and reducing the risk of human error.

AI-driven sanitation systems also play a crucial role in maintaining strict hygiene protocols, minimizing the potential for cross-contamination and safeguarding the integrity of food products. These automated systems, coupled with predictive maintenance, contribute to a comprehensive approach to food safety and quality control.

Regulatory and Safety Considerations

As the food industry embraces these advanced technologies, it must also navigate the complex landscape of regulatory compliance and safety standards. Adherence to frameworks like Hazard Analysis and Critical Control Points (HACCP) and ISO standards is essential to ensure the safety and quality of food products.

AI-driven systems enhance regulatory compliance by automating the analysis of inspection reports, monitoring for deviations, and streamlining documentation. This increased efficiency and transparency also support product traceability, enabling swift responses to potential safety issues and building consumer confidence.

However, the integration of AI and advanced technologies also raises ethical and sustainability concerns that must be addressed. The environmental impact of energy-intensive processing methods and the responsible use of data must be carefully considered to align with the industry’s commitment to sustainability and social responsibility.

Conclusion

The convergence of AI and advanced food processing technologies is revolutionizing the culinary landscape, delivering unprecedented levels of safety, quality, and sustainability. By leveraging the power of machine learning, deep learning, and sensor integration, food producers can optimize operations, enhance product consistency, and ensure the integrity of the supply chain.

As we at The Loch & Quay continue to push the boundaries of culinary excellence, we remain committed to embracing these transformative technologies. Through our dedication to innovation, culinary tradition, and environmental stewardship, we strive to provide our patrons with unforgettable dining experiences that showcase the finest local ingredients, innovative flavors, and unwavering commitment to food safety and quality.